Why braided composite tubes?

The brilliance of TUBETEC lies in two things: the materials we use and the way we manufacture them.

Composite over anything else

It’s no secret that composites offer significant advantages over other materials in terms of strength, rigidity and lightness. Other materials —plastic, steel, aluminum— can’t match this combination of attributes. If you need your part to be strong, light and tough, using composites such as carbon fiber, fiberglass or aramids (Kevlar™) will enable your most audacious designs to be reality!

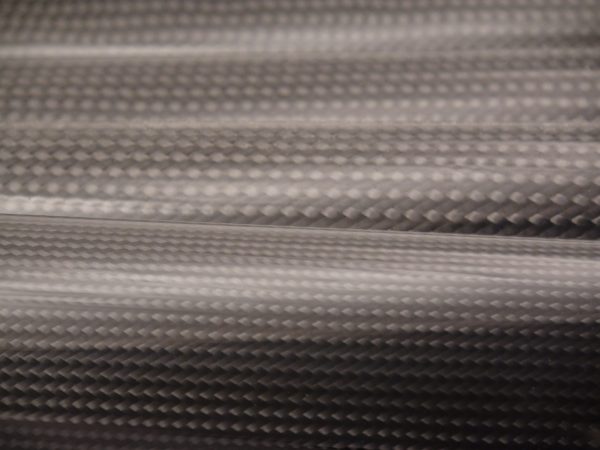

Braided composite tubes over other composite tubes

As good as composite tubes are, braided material makes them unbeatable. A braided composite is preferred over other methods of composite tubing because it takes the advantages of composites and multiplies them. Continuous fiber at defined bi-axial patterns yield light, tough and stiff structures capable of handling complex continuous or sudden loads.

Other molding methods have their own unique attributes and advantages. Let’s see how braided TUBETEC composite tubes compare:

| Process | Dimensional Tolerances | Tooling & Setup Costs | Low Volume OK | Curves & Profiles | Long Length | Custom Ply Structure | Excellent Finish |

|---|---|---|---|---|---|---|---|

| Pultrusion | $$ | ||||||

| Roll Wrap | $$ | ||||||

| Filament Winding | I.D. | $$$ | |||||

| Bladder Molding | O.D. | $$$$ | |||||

| Modified Closed Molding | $$$ | ||||||

| TUBETEC | $ |